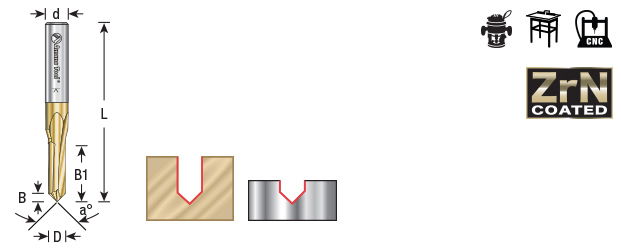

Product Overview

| (a°) Angle | 90° |

|---|---|

| (D) Diameter | 1/4 |

| (B) Cutting Height | 1/8 |

| B1 | 3/4 |

| (d) Shank | 1/4 |

| Overall Length (L) | 2-1/4 |

| Flutes | 2 |

| Chip Load | 0.003" - 0.006" |

Designed for beveling or V-Grooving 90° the following materials:

- Acrylonitrile-Butadiene-Styrene (ABS)

- Aluminum, Brass, Bronze, Copper, Gold & Silver

- Aluminum 5052

- Composites

- Fomex® with Aluminum Face

- Hard Plastics

- Hardwood

- Laminated Chipboard/Plywood

- MDF

- Non-Ferrous Metals

- Polycarbonate (Lexan™)†

- Solid Surfaces (Corian®

Formica® ect) - Soft Plastics

- Softwood

- Veneer

†Recommendation: Use the slowest suggested feed rates and the shortest bits necessary for cutting and routing Lexan™.

Benefits of ZrN Coating

- Creates a harder and tougher cutting edge allows for a prolonged cutting edge life and helps to prevent the build-up of material in the flutes while cutting

- High resistance to wear

- Extended tool life

- Less friction & heat buildup

- High resistance to wear